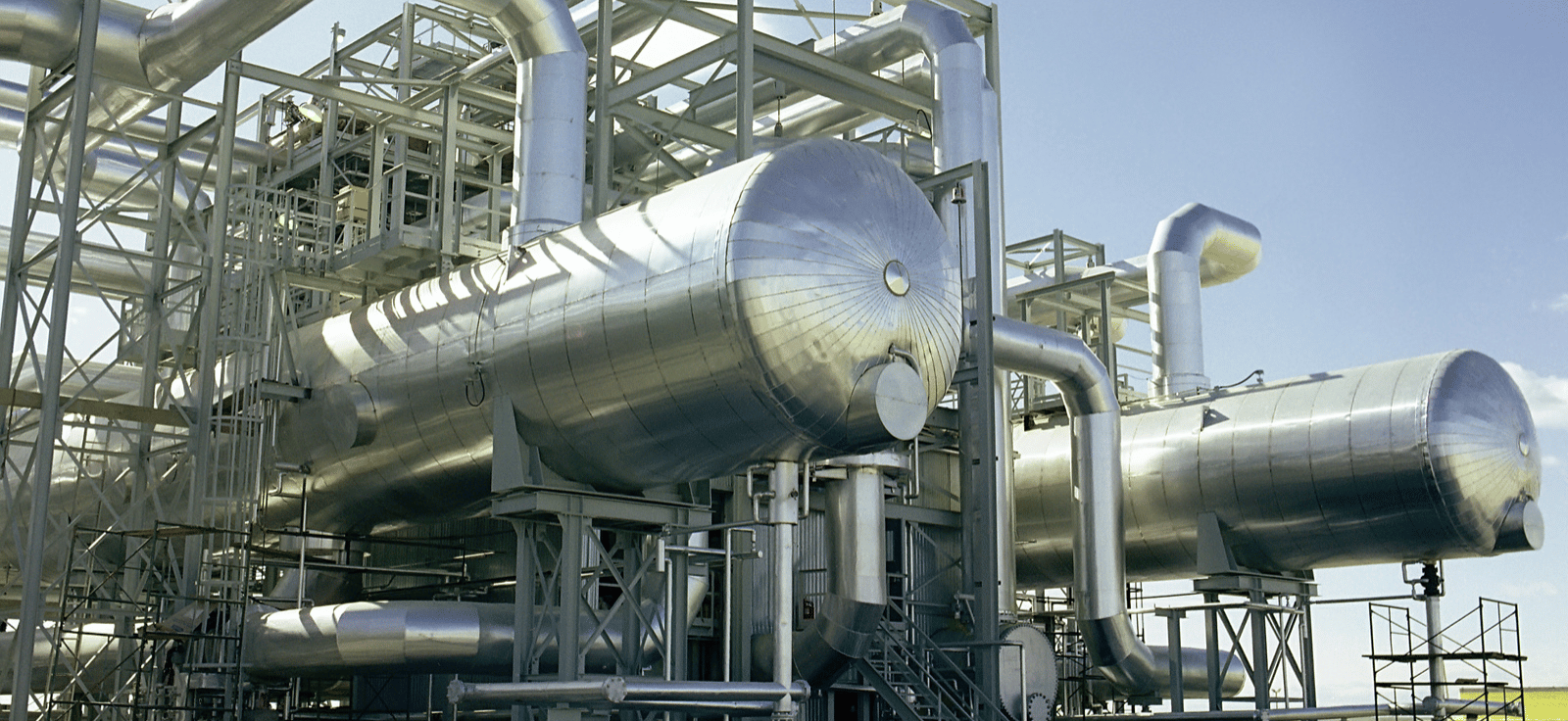

Pressure Vessels Inspection Services

Pressure vessels operate under high pressure and temperature, making them critical—and potentially hazardous—industrial assets. Failures can lead to catastrophic explosions, production loss, environmental harm, serious injuries, and legal liabilities.

BGMC provides independent, third-party Pressure Vessel Inspection Services to ensure that vessels meet international codes, manufacturer requirements, and regulatory standards. Through systematic inspection, testing, and verification, we help clients maintain safe operations, extend asset life, and comply with legal and industry requirements.

Our inspection processes are aligned with ISO/IEC 17020, ensuring impartiality, competence, and technical precision.

Why Pressure Vessel Inspection Is Essential

Without periodic inspection, pressure vessels may suffer from:

Corrosion, pitting, thinning

Cracks & weld defects

Overpressure failures

Internal scaling or deposit formation

Leakage or ruptures

Fatigue due to cyclic loading

Non-compliance with national regulations

Our Inspection Services

Scope of BGMC Pressure Vessel Inspection Services

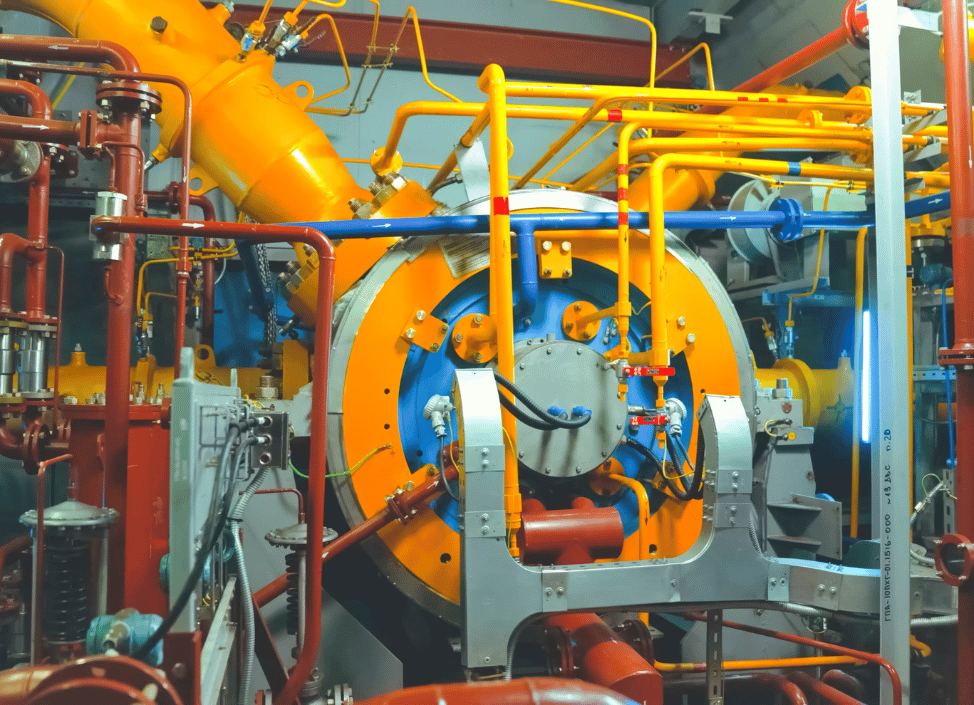

The scope of BGMC’s Pressure Vessel Inspection Services includes evaluating vessel integrity, safety devices, weld quality, corrosion levels, and regulatory compliance to ensure safe, reliable, and efficient operation of pressure-containing equipment.

Visual Inspection

We examine the external shell condition, coatings and insulation, weld seams, supports, saddles and attachments, as well as nozzles and flanges. Internal surface conditions and areas prone to corrosion or erosion are also assessed. Together, these checks establish the baseline condition of the pressure vessel.

Non-Destructive Testing

BGMC provides or coordinates a full range of NDT services, including Ultrasonic Thickness Testing, MPI, DPI, Radiography, PAUT, TOFD, and Eddy Current Testing for applicable components. These methods help detect hidden defects that cannot be identified through visual inspection alone, ensuring a more complete assessment of vessel integrity.

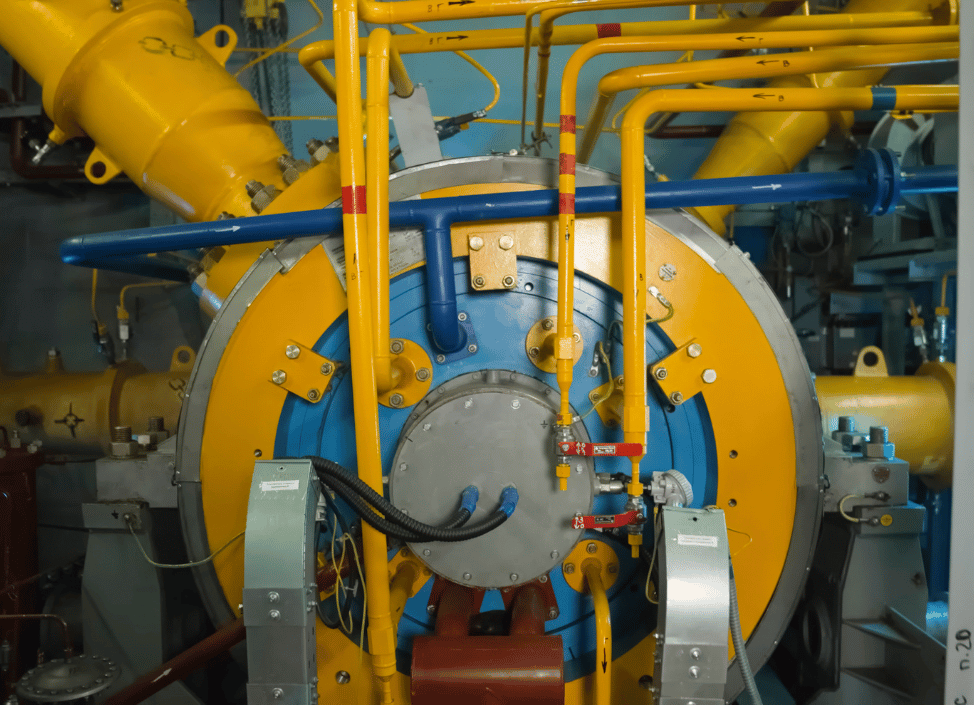

Pneumatic Pressure Testing

To confirm vessel strength and integrity, we support hydrostatic pressure tests, pneumatic pressure tests where allowed by standards, and pressure hold and leakage observations, along with full safety monitoring during execution. These tests validate vessel performance under controlled stress conditions and ensure safe operational readiness.

Inspection During Fabrication

We conduct third-party inspections throughout all manufacturing stages, including material certificate verification, fit-up and weld inspections, WPS/PQR/WPQ verification, dimensional checks, NDT witnessing, and final pressure test and closure inspections. This ensures each pressure vessel is built in full compliance with ASME, EN, or customer-specific requirements.

In-Service Periodic Inspection

During operation, we evaluate corrosion rate trends, thickness loss, internal scaling or fouling, the condition of safety valves, nameplate compliance, and the health of accessories and instrumentation. These checks ensure ongoing integrity and support compliance with statutory and client requirements.

Fitness-for-Service (FFS) Assessment

For aging, damaged, or non-conforming vessels, BGMC provides remaining life assessments, API 579 evaluations, repair and alteration recommendations, and continued service suitability analysis. These evaluations help organizations determine whether a vessel should be repaired, derated, reused, or retired.

Why Choose BGMC for Pressure Vessel Inspection?

ISO/IEC 17020–aligned inspection approach

Qualified inspectors for ASME, API 510 & PED

Integrated NDT and mechanical testing support

Clear, evidence-based inspection reports

Experience across high-risk industrial sectors

Oil & Gas

Petrochemical

Chemical & Fertilizer Plants

Power Generation

Manufacturing & Heavy Industry

Reactors

Heat exchangers

Air receivers

Storage tanks

Separators

Sample Use Cases

How It Works

Case 1: In-Service Pressure Vessel Compliance Audit

A chemical plant required a full inspection to meet statutory requirements. BGMC conducted external and internal examinations, thickness gauging, safety valve checks, and operational assessments. The vessel passed compliance review with all critical risks addressed.

Case 2: New Vessel Fabrication & Third-Party Verification

A manufacturing company needed independent oversight during vessel fabrication. BGMC verified material certificates, welding qualifications, dimensional accuracy, NDT results, and hydrotest performance, ensuring the vessel met ASME Section VIII standards before dispatch.

Case 3: Remaining Life & Fitness-for-Service Evaluation

An aging refinery vessel showed signs of corrosion and thinning. BGMC performed API 579 assessments, corrosion rate analysis, and suitability-for-service evaluation. Recommendations enabled safe continued operation with defined monitoring intervals.

successful projects & satisfied customers.

Inspired by our work?

Want to ensure the safety, compliance, and long-term performance of your pressure vessels?

BGMC provides reliable, independent, and technically robust pressure vessel inspection solutions.