Lean Six Sigma Certification Training

Unlock your potential with Lean Six Sigma Certification, the global benchmark for excellence in quality management and process improvement.

Our training empowers professionals with the tools to reduce waste, enhance quality, optimise performance, and drive measurable business results.

Lean Six Sigma Certification Training

Lean Six Sigma Yellow Belt

accredited by

Our Six Sigma course is accredited by Six Sigma

Duration

- Online Instructor-led (5 days)

- Classroom (5 days)

- Online Self-paced (40 hours)

exam

- Official Lean Six Sigma Yellow Belt and Green Belt Exams

Lean Six Sigma Yellow Belt – Course Outline

Module 1: Introduction to Lean Six Sigma

- Understanding Lean Six Sigma

- The Two Core Components of Lean Six Sigma

- The Focus and Philosophy of Lean

- The Lean Temple Model

- The Focus and Principles of Six Sigma

- Delivering Customer Satisfaction

- How Lean and Six Sigma Complement Each Other

- Key Principles and Concepts of Lean Six Sigma

- Overview of the Belt Hierarchy

- Overview of the Belt Hierarchy

- The Lean Six Sigma Support Network

• Understanding Processes

- Different Perspectives on Process Improvement

- What is a Process?

- Core Process Concepts and Classifications

- Types of Processes and How They Differ

- Understanding Customers, Value, and Waste

• Value and Waste in Processes

- Identifying Customers and Their Needs

- Voice of the Business (VOB) vs. Voice of the Customer (VOC)

- Defining “Value” and Creating a Path to Value

- Managing and Eliminating Waste (Muda)

- The Seven Wastes of Lean

- Understanding Types of Demand

- The Seven Wastes of Lean

- Demand Types and Flow Efficiency

- Case Study Exercise: Identifying Value and Waste

Read MoreLess

Module 2: The DMAIC Cycle

- Overview of the DMAIC Framework (Define, Measure, Analyse, Improve, Control)

• Define Phase

- Objectives of the Define Phase

- Key Tools for Define Phase

- Gemba Walks and Process Stapling

• Measure Phase

- Importance of Measurement

- Key Tools for the Measure Phase

- Key Tools for the Measure Phase

• Analyse Phase

- Analysing Processes to Identify Root Causes

- Common Tools for the Analyse Phase

• Improve Phase

- Generating and Testing Solutions

- Tools for Continuous Process Improvement

• Control Phase

- Sustaining Improvements

- Control Tools and Visual Management

Module 3: Yellow Belt Tools and Techniques

Core Lean Tools

- The Lean Triad

- 5S Workplace Organisation

- Poka-Yoke (Error Proofing)

- SMED (Single-Minute Exchange of Die)

• Voice of the Customer (VOC) and Critical-to-Quality (CTQ)

- Understanding VOC and Its Importance

- Customer Chains and Flow of Requirements

- Steps to Capture VOC

- Using Affinity and Kano Diagrams

- Translating VOC into CTQs and Measurable Requirements

• SIPOC and Value Stream Mapping

- What is SIPOC and Why It Matters

- Creating a SIPOC Diagram

- Example: CSandF Web Fulfilment SIPOC

- Best Practices for SIPOC Development

- Value Stream Mapping Concepts

- Process Mapping and Swimlane Diagrams

- Example: Value Stream Mapping for “Headache Tablets”

• Flow and Production Concepts

- Understanding Heijunka (Production Leveling)

- The Principle of Single Piece Flow

- Pull Systems and Kanban Boards

- Three-Bin System and Material Flow

- Andon and Visual Control

• Problem Solving and Root Cause Analysis

- The 5 Whys Technique

- Fishbone (Ishikawa) Diagrams

- Structured Problem-Solving Frameworks

- Prioritisation Tools and Decision Matrices

- Tools for Generating Effective Solutions

• Kaizen and Continuous Improvement

- Introduction to Kaizen Philosophy

- Applying Kaizen in a Business Setting

- Building and Leading Lean Teams

- Managing Progress and Demonstrating Control

Who Should Attend the Lean Six Sigma Yellow Belt Course

The Lean Six Sigma Yellow Belt Training is ideal for individuals seeking to understand the fundamentals of process improvement, waste reduction, and quality enhancement within any business environment. It serves as an essential first step for those beginning their Lean Six Sigma journey or supporting improvement projects within their organisations.

This course is particularly beneficial for:

- Entry-level professionals and new graduates aspiring to build a foundation in process improvement

- Team members working on Lean Six Sigma or quality initiatives

- Supervisors and frontline staff involved in daily process operations

- Quality, Production, and Process Assistants

- Administrative, Finance, and HR personnel looking to streamline workflows

- Anyone interested in learning how to improve efficiency, eliminate waste, and contribute to continuous improvement initiatives

What’s Included in the Lean Six Sigma Yellow Belt Course

Enrolling in the Lean Six Sigma Yellow Belt Training gives delegates access to a complete and engaging learning experience, designed to build a strong foundation in process improvement and quality management.

This course package includes:

🎓 Lean Six Sigma Yellow Belt Examination – Evaluate your understanding of Lean Six Sigma fundamentals through a structured assessment.

👨🏫 Expert-Led Training Sessions – Delivered by certified Lean Six Sigma practitioners with real-world project experience.

📜 Globally Recognised Yellow Belt Certification – Awarded upon successful completion of the training and examination.

💻 Digital Delegate Pack – Includes comprehensive course materials, study guides, templates, and practical exercises.

📈 Practical Case Studies & Simulations – Hands-on activities designed to reinforce key Lean Six Sigma tools and methodologies.

Lean Six Sigma Yellow Belt Examination

To achieve the Lean Six Sigma Yellow Belt Certification, delegates must successfully pass a structured examination designed to assess their understanding of Lean Six Sigma principles, methodologies, and basic tools for process improvement.

Exam Details:

Question Type: Multiple Choice and Scenario-Based

Total Questions: 40

Passing Score: 70%

Duration: 1 Hour

Exam Format: Closed Book

This assessment ensures that participants can demonstrate a sound grasp of Lean Six Sigma fundamentals, including waste identification, process mapping, and continuous improvement concepts.

Upon passing the exam, delegates are awarded the Lean Six Sigma Yellow Belt Certificate, which validates their foundational knowledge and ability to contribute effectively to Lean Six Sigma projects within their organisation.

PHYSICAL CLASSES

Face-to-face, classroom-based, instructor-led learning

- Instructor-led Lean Six Sigma Yellow Belt training

- Core Lean concepts & Six Sigma fundamentals

- Hands-on process improvement activities

- Real-world examples and group exercises

- Yellow Belt Certificate upon successful completion

Online Classes

Flexible, live, instructor-led virtual learning

- Live virtual Lean Six Sigma Yellow Belt sessions

- Interactive problem-solving and case discussions

- Digital study materials and templates

- Instructor guidance and Q&A support

- Digital Yellow Belt Certificate

Enterprise Solutions

Scalable Lean Six Sigma Yellow Belt programs for organizations

Contact For Price

- Organization-wide Yellow Belt capability building

- Customized training aligned with business processes

- Practical improvement project support

- Performance and impact tracking

- Cost-effective, scalable deployment

E-LEARNING

Self-paced, structured Lean Six Sigma digital learning

- Self-paced Lean Six Sigma Yellow Belt modules

- Full access to course content anytime

- Practical tools, worksheets, and templates

- Knowledge checks and quizzes

- Certificate upon course completion

Lean Six Sigma Green Belt – Course Outline

accredited by

Our Six Sigma course is accredited by Six Sigma

Duration

- Online Instructor-led (5 days)

- Classroom (5 days)

- Online Self-paced (40 hours)

exam

- Official Lean Six Sigma Yellow Belt and Green Belt Exams

Lean Six Sigma Green Belt – Course Outline

Module 1: Introduction to Lean Six Sigma

• What is Lean 6 Sigma?

- What is Lean Six Sigma?

- The Dual Foundation: Lean and Six Sigma

- Lean Philosophy and Key Focus Areas

- The Lean Temple Framework

- The Purpose and Power of Six Sigma

- Delivering Customer Satisfaction

- How Lean and Six Sigma Work Together

- Key Principles and Mindsets of Lean Six Sigma

- Understanding the Belt Hierarchy

- Green Belt Role and Responsibilities

- Lean Six Sigma Support Infrastructure

• Process Fundamentals

- Understanding “Process” and Process Thinking

- Types and Classifications of Processes

- Comparing Different Process Categories

- Core Process Concepts in Improvement Initiatives

- Linking Customers, Value, and Waste

• Value, Waste, and the Customer

- Identifying Internal and External Customers

- Understanding Outputs and Customer Expectations

- The Balance Between VOC (Voice of the Customer) and VOB (Voice of the Business)

- Defining “Value” in Lean Context

- Value Creation Pathways

- Eliminating Waste (Muda)

- The Seven Wastes of Lean

- Demand Types and Flow Efficiency

- Case Study Exercise: Identifying Value and Waste

Our Accreditation Partners

Read MoreLess

• Measuring What Matters

- Key Metrics for Process Efficiency and Performance

Module 2: The DMAIC Methodology

- Introduction to the DMAIC Framework (Define, Measure, Analyze, Improve, Control)

• Define Phase

- Purpose of the Define Stage

- Project Charters and Problem Statements

- Stakeholder Analysis and SIPOC Development

- Common Define Phase Tools

- Gemba Walks and Process Stapling

• Measure Phase

- Purpose of the Measure Stage

- Understanding Data Types and Measurement Systems

- Measurement Tools and Techniques

- Spaghetti Diagrams and Waste Analysis

- Establishing Baseline Performance

• Analyze Phase

- Identifying Root Causes

- Using Analytical and Statistical Tools

- Process Mapping and Cause-and-Effect Analysis

- Hypothesis Testing and Data Interpretation

• Improve Phase

- Generating and Implementing Effective Solutions

- Applying Lean Tools to Eliminate Waste

- Error-Proofing (Poka-Yoke) and Process Simplification

- Conducting Pilot Runs and Evaluating Results

• Control Phase

- Sustaining the Gains

- Standardization and Control Plans

- Visual Management and Auditing Tools

- Statistical Process Control (SPC) for Ongoing Monitoring

Module 3: Advanced Green Belt Tools and Techniques

Lean Tools for Process Optimization

- The Lean Triad and Continuous Flow

- 5S Workplace Organization

- SMED (Quick Changeover)

- Heijunka (Production Leveling)

- Kanban and Pull Systems

- Andon Visual Control Mechanisms

• Voice of the Customer (VOC) and Critical-to-Quality (CTQ)

- Gathering and Interpreting VOC

- Translating Customer Needs into CTQs

- Kano Model and Affinity Diagrams

- Linking VOC to Business Objectives

• SIPOC and Value Stream Mapping

- Understanding and Creating SIPOC Diagrams

- Mapping Processes for Clarity and Improvement

- Value Stream Mapping (VSM) Concepts and Terminology

- Swimlane Diagrams and Typical Map Components

- Example: “Headache Tablets” Value Stream Mapping Exercise

• Statistical and Analytical Tools

- Introduction to Statistical Process Control (SPC)

- Understanding Process Variation

- The Red Bead Experiment

- Standard Deviation and Control Charts

- Defect Measurement and DPMO Calculations

- Process Capability and Sigma Levels

- Assessing Process Efficiency and Effectiveness

• Root Cause Analysis and Problem Solving

- 5 Whys and Fishbone (Ishikawa) Diagrams

- Data-Driven Decision-Making Frameworks

- Prioritization Tools (PICK Charts, Pareto Analysis)

- Generating and Selecting Effective Solutions

• Kaizen and Continuous Improvement

- Kaizen Philosophy and Practical Application

- Running Kaizen Events

- Embedding a Culture of Continuous Improvement

• Team Dynamics and Project Management

- Roles and Responsibilities of Green Belts in Projects

- Building and Leading Lean Teams

- Managing Stakeholders and Communication

- Tracking Progress and Demonstrating Control

Who Should Attend the Lean Six Sigma Green Belt Course

The Lean Six Sigma Green Belt Training Course is ideal for professionals seeking to enhance business performance, streamline operations, and implement quality improvement initiatives across any industry. This certification empowers individuals to drive measurable change within their organisations through data-driven decision making and structured problem solving.

This course is particularly beneficial for:

- Operations Managers and Supervisors

- Quality Assurance and Control Professionals

- Project Managers and Team Leaders

- Manufacturing and Process Engineers

- Business and Data Analysts

- Financial Analysts and Risk Professionals

- IT and Process Automation Experts

- Supply Chain and Logistics Specialists

Prerequisites

There are no formal prerequisites for enrolling in the Lean Six Sigma Green Belt Training Course. However, prior exposure to process management, operations, or quality improvement roles can be advantageous.

Familiarity with basic statistical concepts will also help delegates better understand the analytical aspects of Six Sigma, though it is not mandatory for participation.

Course Overview

The Lean Six Sigma Green Belt Training provides delegates with an in-depth understanding of the combined Lean and Six Sigma methodologies—integrating Lean’s focus on efficiency with Six Sigma’s emphasis on precision and quality.

- Leading process improvement initiatives

- Identifying inefficiencies and bottlenecks

- Analysing data to determine root causes

- Implementing structured solutions to enhance quality and performance

This intensive 5-day training blends theory with hands-on application, ensuring participants can immediately apply Lean Six Sigma tools within their work environments. Upon completion, delegates are equipped to lead improvement projects, make data-driven decisions, and deliver measurable business results.

Read MoreLess

Learning Objectives

- By the end of the course, delegates will be able to:

- Understand the principles, framework, and benefits of Lean Six Sigma.

- Identify and systematically eliminate waste from business processes.

- Apply Six Sigma methodologies to address quality and variation issues.

- Implement Lean tools to improve productivity and workflow efficiency.

- Analyse and interpret data to support informed decision-making.

- Lead improvement teams and sustain process excellence within their organisations.

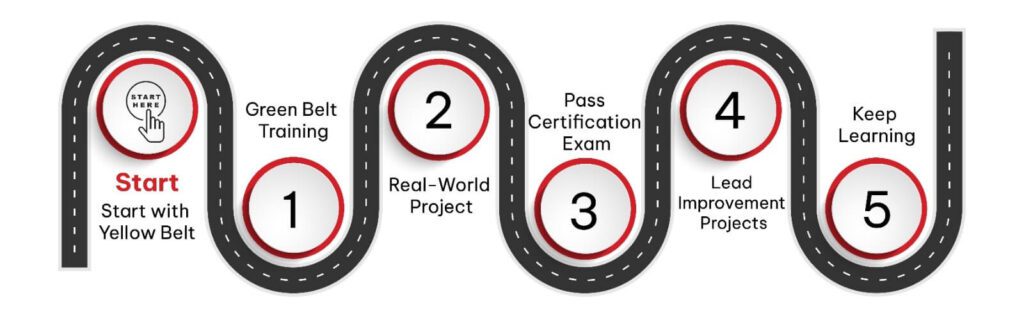

Roadmap to Mastering Lean Six Sigma Green Belt

Start with Yellow Belt – Gain a foundational understanding of Lean Six Sigma principles, terminology, and basic tools.

Advance to Green Belt – Develop intermediate-level expertise in process improvement, problem-solving, and statistical analysis.

Undertake a Real-World Project – Apply classroom knowledge to practical business challenges and deliver measurable outcomes.

Pass the Certification Exam – Validate your skills and earn the internationally recognised Green Belt credential.

Lead Process Improvement Projects – Take ownership of initiatives that boost efficiency, reduce defects, and elevate customer satisfaction.

Continue Learning and Growing – Progress toward advanced certifications (Black Belt, Master Black Belt) and enhance your leadership capabilities.

What’s Included in the Lean Six Sigma Green Belt Course

This comprehensive course package includes:

🎓 Lean Six Sigma Yellow Belt Examination – Assess your foundational knowledge and understanding of core Lean Six Sigma concepts.

🎓 Lean Six Sigma Green Belt Examination – Validate your advanced proficiency and readiness to lead process improvement projects.

👨🏫 World-Class Training Sessions – Delivered by experienced industry practitioners with real-world project expertise.

📜 Globally Recognised Green Belt Certification – Official certificate awarded upon successful completion of the course and exam.

💻 Digital Delegate Pack – Includes detailed course notes, templates, exercises, and reference materials for lifelong learning.

Lean Six Sigma Green Belt Qualification

The Lean Six Sigma Green Belt Qualification represents the second level in the Lean Six Sigma certification pathway. It equips professionals with advanced analytical skills, practical problem-solving techniques, and leadership capabilities required to manage process improvement initiatives within their organisations.

Lean Six Sigma Green Belt Examination

Exam Details:

Question Type: Multiple Choice

Total Questions: 100 to 150

Passing Score: 70%

Duration: 2 Hours

Format: Closed Book

Upon passing the examination, delegates are awarded the Lean Six Sigma Green Belt Certificate, a globally recognised credential demonstrating proficiency in process optimisation, quality management, and continuous improvement leadership.

This qualification empowers professionals to:

Lead process improvement teams and projects.

Apply data-driven problem-solving methodologies.

Drive measurable enhancements in quality, efficiency, and customer satisfaction.

PHYSICAL CLASSES

Face-to-face, classroom-based, instructor-led learning

- Instructor-led Lean Six Sigma Green Belt training

- Advanced Lean techniques and Six Sigma tools

- Hands-on process improvement projects

- Practical exercises and case studies

- Green Belt Certification upon completion

Online Classes

Flexible, live, instructor-led virtual learning

- Live virtual Lean Six Sigma Green Belt sessions

- Advanced problem-solving techniques and group activities

- Access to digital learning resources and tools

- Instructor support and feedback throughout

- Digital Green Belt Certificate

Enterprise Solutions

Contact For Price

- Customized Green Belt training for teams and departments

- Aligning Lean Six Sigma with organizational goals

- Support for implementing process improvement projects

- Tracking performance and measurable outcomes

- Cost-effective deployment across teams

E-LEARNING

Self-paced, structured Lean Six Sigma digital learning

- Self-paced Lean Six Sigma Green Belt modules

- Full course access to advanced Green Belt topics

- Practical tools, templates, and real-world scenarios

- Interactive assessments and quizzes

- Certification upon course completion

Lean Six Sigma Black Belt

accredited by

Our Six Sigma course is accredited by Six Sigma

Duration

- Online Instructor-led (5 days)

- Classroom (5 days)

- Online Self-paced (40 hours)

exam

- Official Lean Six Sigma Yellow Belt and Green Belt Exams

Lean Six Sigma Green Belt – Course Outline

Module 1: Introduction to Lean Six Sigma

• What is Lean 6 Sigma?

- Evolution of Lean and Six Sigma

- The Philosophy of Continuous Improvement

- Roles and Responsibilities of Black Belts

- The Business Case for Lean Six Sigma

- Organisational Alignment and Strategic Deployment

- Linking Lean Six Sigma to Business Objectives

- Overview of Lean Principles and Six Sigma Methodology

- DMAIC vs. DMADV – Choosing the Right Approach

- Key Success Factors for Lean Six Sigma Implementation

- Change Management and Leadership in Lean Six Sigma Projects

Module 2: The DMAIC Methodology

- Defining Core and Support Processes

- Value Stream Management for Enterprise-Level Improvement

- Process Ownership and Governance

- Cross-Functional Process Mapping and Swimlane Diagrams

- SIPOC at an Organisational Level

- Aligning Processes to Strategic Goals

Module 3: The DMAIC Methodology – Black Belt Mastery

• Define Phase

- Developing Project Charters and Business Cases

- Advanced Stakeholder and Communication Planning

- Voice of the Customer (VOC) and Voice of the Process (VOP)

- Translating VOC into CTQ Requirements

- Selecting and Prioritising Projects

- Gemba Walks and Problem Scoping

Read MoreLess

• Measure Phase

- Measurement System Analysis (MSA)

- Gauge R&R Studies

- Data Collection and Sampling Strategies

- Process Capability Analysis (Cp, Cpk, Pp, Ppk)

- Data Integrity and Baseline Performance Metrics

- Statistical Tools for Process Measurement

• Analyse Phase

- Root Cause Analysis Techniques

- Correlation and Regression Analysis

- Hypothesis Testing and Confidence Intervals

- Chi-Square, ANOVA, and Non-Parametric Tests

- Failure Mode and Effects Analysis (FMEA)

- Identifying Key Input and Process Variables

- Multi-Vari Charts and Advanced Pareto Analysis

• Improve Phase

- Design of Experiments (DOE) – Full and Fractional Factorial Designs

- Optimisation Techniques and Response Surface Methodology (RSM)

- Process Redesign and Lean Integration

- Mistake-Proofing (Poka-Yoke) at Scale

- Implementing Kaizen and Rapid Improvement Events

- Risk Mitigation and Implementation Planning

• Control Phase

- Statistical Process Control (SPC) and Control Chart Interpretation

- Developing and Executing Control Plans

- Lean Auditing and Visual Management Systems

- Documentation and Standardisation

- Project Closure and Handover

- Sustaining Improvements through a Continuous Improvement Culture

Module 4: Lean Leadership and Organisational Transformation

- Building a Continuous Improvement Culture

- Leading Cross-Functional Teams

- Coaching and Mentoring Green and Yellow Belts

- Stakeholder Engagement and Conflict Resolution

- Organisational Change Management

- Aligning Lean Six Sigma with Strategic KPIs

- Integrating Lean Six Sigma into Business Systems (ISO, QMS, etc.)

- Communicating Results to Executive Leadership

Module 5: Data Analytics and Decision-Making

- Introduction to Advanced Data Analysis

- Statistical Thinking for Business Excellence

- Process Simulation and Modelling

- Control Charts for Variable and Attribute Data

- Measurement of Financial Benefits and ROI

- Using Minitab or Excel for Statistical Computations

- Data-Driven Decision-Making Frameworks

Module 6: Project Execution and Case Studies

- End-to-End Lean Six Sigma Project Management

- Project Selection, Scoping, and Chartering

- Risk Assessment and Mitigation Strategies

- Real-World Case Studies from Multiple Sectors

- Measuring and Reporting Project Success

- Presenting Results to Management and Stakeholders

Module 7: Preparing for Certification

- Review of Core Concepts and Key Tools

- Mock Assessment and Practice Questions

- Exam Preparation Techniques

- Professional Development Path: From Black Belt to Master Black Belt

Who Should Attend the Lean Six Sigma Black Belt Course

The Lean Six Sigma Black Belt Training is designed for experienced professionals who aim to lead complex process improvement initiatives, manage cross-functional teams, and drive strategic change within their organisations. This advanced certification is ideal for individuals seeking to elevate their analytical, leadership, and project management capabilities to deliver measurable business impact.

This course is particularly beneficial for:

- Senior Operations and Quality Managers

- Process Improvement and Business Excellence Professionals

- Project Managers and Continuous Improvement Leaders

- Supply Chain and Logistics Managers

- Data and Business Analysts seeking to apply statistical problem-solving

- Consultants involved in performance optimisation and transformation projects

- Green Belt certified professionals aspiring to advance to the next level

What’s Included in the Lean Six Sigma Black Belt Course

This comprehensive course includes:

🎓 Lean Six Sigma Black Belt Examination – A rigorous assessment to validate advanced understanding of Lean Six Sigma methodologies and analytical tools.

👨🏫 Expert-Led Training Sessions – Delivered by seasoned Master Black Belt practitioners with extensive real-world project experience.

📘 Comprehensive Course Material – Detailed manuals, toolkits, and project templates designed to support both study and implementation.

📜 Globally Recognised Black Belt Certification – Awarded upon successful completion of the course and examination, signifying professional mastery.

💻 Digital Delegate Pack – Includes case studies, exercises, data templates, and reference resources for continued application.

🧩 Practical Case Studies & Group Exercises – Real-life simulations that reinforce statistical, analytical, and managerial problem-solving skills.

💬 Post-Training Support – Guidance for project completion, mentoring for Green Belts, and assistance in preparing for higher-level certifications.

Lean Six Sigma Black Belt Examination

Lean Six Sigma Green Belt Examination

Exam Details:

Question Type: Multiple Choice

Total Questions: 120 to 150

Passing Score: 70%

Duration: 2 Hours

Format: Closed Book

Assessment Focus :

Advanced statistical tools and data analysis

Process optimisation and Design of Experiments (DOE)

Change management and leadership principles

Strategic deployment of Lean Six Sigma across the enterprise

Control planning and sustainability of improvement outcomes

PHYSICAL CLASSES

- Instructor-led Black Belt training

- Mastery of advanced Lean Six Sigma tools

- Real-world case studies and projects

- In-depth understanding of process improvement

- Black Belt Certification upon completion

Online Classes

- Live sessions with advanced problem-solving

- Focus on leadership and project management

- Access to digital learning resources

- Ongoing instructor support and mentorship

- Digital Black Belt Certification

Enterprise Solutions

Contact For Price

- Tailored programs aligned with business strategies

- Support for large-scale process improvements

- Focus on enterprise-wide transformation

- Performance tracking and reporting

- Scalable and cost-effective deployment

E-LEARNING

- Self-paced Black Belt modules

- Comprehensive tools and templates

- Real-world applications and scenarios

- Knowledge checks and assignments

- Black Belt Certification upon completion

Lean Six Sigma Master Black Belt (MBB)

accredited by

Our Six Sigma course is accredited by Six Sigma

Duration

- Online Instructor-led (5 days)

- Classroom (5 days)

- Online Self-paced (40 hours)

exam

- Official Lean Six Sigma Yellow Belt and Green Belt Exams

Lean Six Sigma Master Black Belt (MBB) – Course Outline

Module 1: The Role of the Master Black Belt

- Evolution from Black Belt to Master Black Belt

- Strategic Responsibilities and Leadership Expectations

- Coaching and Mentoring Black and Green Belts

- Enterprise Deployment and Governance of Lean Six Sigma

- Aligning Lean Six Sigma with Corporate Strategy

- Building a Culture of Continuous Improvement

Module 2: Organisational Excellence and Strategic Deployment

- Lean Six Sigma as a Business Transformation Framework

- Selecting, Prioritising, and Managing Project Portfolios

- Creating the Lean Six Sigma Deployment Plan

- Integrating with Business Systems (ISO, QMS, ESG, etc.)

- Organisational Change Management and Stakeholder Alignment

- Leadership Communication and Executive Engagement

Module 3: Advanced Analytical and Statistical Methods

- Advanced Design of Experiments (DOE) and Response Surface Methodology

- Multivariate Analysis, Regression, and Correlation Techniques

- Time Series Analysis and Forecasting

- Reliability Engineering and Life Data Analysis

- Simulation and Modelling for Process Optimisation

- Using Minitab or Statistical Software for Complex Analysis

Read MoreLess

Module 4: Lean Innovation and Design for Six Sigma (DFSS)

- DMADV Methodology and Innovation Framework

- Quality Function Deployment (QFD)

- Design Thinking and Voice of the Customer (VOC) Integration

- Risk Management: FMEA and Fault Tree Analysis (FTA)

- Concept and Prototype Validation Techniques

- Process and Product Design Optimisation

Module 5: Leadership, Coaching, and Organisational Influence

- Developing Leadership Presence and Influencing at Executive Level

- Coaching Black Belts and Building High-Performance Teams

- Managing Conflict and Facilitating Cross-Functional Collaboration

- Executive Communication and Reporting Metrics

- Ethical Leadership and Data Integrity

- Training Design and Curriculum Development for Internal Programs

Module 6: Advanced Lean Enterprise Tools

- Enterprise Value Stream Mapping (EVSM)

- Lean Enterprise Maturity and Cultural Assessment

- Total Productive Maintenance (TPM) and Reliability-Based Improvement

- Hoshin Kanri (Policy Deployment)

- Managing Lean Office and Service Environments

- Digital Lean and Industry 4.0 Applications

Module 7: Financial and Strategic Impact Analysis

- Quantifying Financial Benefits of Improvement Projects

- Cost of Quality and ROI Calculation

- Balanced Scorecards and Strategic Metrics

- Linking Operational Excellence to Business Growth

- Executive-Level Decision Support Models

Module 8: Case Studies, Coaching, and Project Reviews

- Reviewing and Evaluating Black Belt Projects

- Coaching for Organisational Deployment and Cultural Change

- Global Case Studies from Manufacturing, Services, and Healthcare

- Best Practices in Sustaining Excellence

- Final Project Presentation and Review Panel

Who Should Attend the Lean Six Sigma Master Black Belt (MBB) Course

The Lean Six Sigma Master Black Belt (MBB) Training is designed for experienced Lean Six Sigma professionals who are ready to move from leading projects to leading transformation. This course is intended for those who want to mentor, coach, and strategically guide Lean Six Sigma deployments at the organisational and enterprise levels

This course is particularly beneficial for:

- Certified Lean Six Sigma Black Belts seeking to advance to the Master level

- Senior Quality, Operations, and Excellence Leaders

- Directors and Heads of Continuous Improvement or Process Excellence

- Business Transformation and Strategy Professionals

- Corporate Trainers and Internal Lean Six Sigma Coaches

- Consultants responsible for large-scale improvement programs

- Executives aiming to integrate Lean Six Sigma into organisational strategy

What’s Included in the Lean Six Sigma Master Black Belt (MBB) Course

The Lean Six Sigma Master Black Belt (MBB) Training delivers a complete professional development experience for seasoned Lean Six Sigma leaders aspiring to master strategic transformation, executive leadership, and enterprise-level deployment of continuous improvement.

This elite program includes:

🎓 Lean Six Sigma Master Black Belt Examination – A rigorous final assessment that validates mastery of advanced analytical, strategic, and leadership competencies.

👨🏫 World-Class Instruction by Industry Experts – Delivered by globally certified Master Black Belts with extensive leadership and consulting experience across sectors.

📘 Comprehensive Learning Materials – Includes advanced toolkits, frameworks, project templates, and case studies to support strategic deployment.

📜 Globally Recognised Master Black Belt Certification – Awarded upon successful completion, certifying expertise in Lean Six Sigma leadership, coaching, and transformation.

💻 Digital Delegate Pack – Access to learning materials, data files, models, and deployment templates in digital format for long-term use.

🧩 Practical Case Studies and Executive Simulations – Real-world scenarios that challenge participants to solve high-impact organisational problems.

💬 Mentorship and Leadership Coaching – Ongoing post-training support to help participants implement enterprise-level improvement frameworks and mentor internal teams.

Lean Six Sigma Master Black Belt (MBB) Examination

To achieve the Lean Six Sigma Master Black Belt (MBB) Certification, delegates must successfully complete an extensive examination that validates their strategic, analytical, and leadership proficiency in driving large-scale, enterprise-level process improvement.

Exam Details:

Question Type: Multiple Choice

Total Questions: 50

Passing Score: 70%

Duration: 2 Hours

Format: Closed Book

Assessment Focus

The Master Black Belt examination evaluates mastery in:

Strategic deployment of Lean Six Sigma across enterprises

Advanced analytics and Design for Six Sigma (DFSS)

Organisational change management and cultural transformation

Coaching, mentoring, and leadership development

Financial and strategic impact measurement

Business excellence frameworks and integration with management systems

Upon successful completion, participants are awarded the Lean Six Sigma Master Black Belt Certification, a globally prestigious credential that recognises their ability to lead enterprise-wide excellence programs, coach senior practitioners, and drive strategic transformation within complex organisations.

PHYSICAL CLASSES

Instructor-led, face-to-face learning

- Comprehensive Master Black Belt training

- Leadership and strategy tools

- Mastery of process improvement methods

- Real-world projects and case studies

- Master Black Belt Certification

Online Classes

- Live leadership and strategy sessions

- In-depth Six Sigma methodologies

- Digital resources and templates

- Ongoing expert guidance

- Digital Master Black Belt Certification

Enterprise Solutions

Contact For Price

- Tailored programs for business goals

- Support for transformation initiatives

- Process optimization project support

- Performance tracking and reporting

- Cost-effective solutions for organizations

E-LEARNING

- Self-paced Master Black Belt modules

- Tools and strategic methodologies

- Access to resources and examples

- Knowledge checks and assignments

- Master Black Belt Certification

Not Sure Which Course is Right for You?

Lean Six Sigma Certification Training – Frequently Asked Questions

What is Lean Six Sigma Certification?

Lean Six Sigma Certification enhances your quality improvement skills by combining process efficiency with data-driven decision-making. It empowers professionals to reduce waste, improve productivity, and optimise business performance through structured methodologies and proven analytical tools.

What does each Lean Six Sigma certification level cover?

Each certification level introduces progressive Lean Six Sigma concepts:

Yellow Belt: Foundation in process improvement and basic problem-solving tools.

Green Belt: Intermediate level focused on data analysis and project execution.

Black Belt: Advanced level for managing complex projects and leading cross-functional teams.

Master Black Belt: Strategic leadership and enterprise-wide deployment.

What are the benefits of Lean Six Sigma Certification training?

What will I learn in Lean Six Sigma Certification training?

Which Lean Six Sigma Certification is best for beginners?

Do I need prior experience in project management to take this course?

Can I take Lean Six Sigma training while working full-time?

Yes, training is designed to accommodate working professionals. Flexible learning options are available, including weekend, evening, and online self-paced sessions, allowing you to balance work and study effectively.

Is the exam included in Lean Six Sigma Certification training?

Yes, the official examination is included in all Lean Six Sigma Certification courses. Upon passing the exam, participants receive a globally recognised certification verifying their competency at the respective Belt level.

What is the duration of Lean Six Sigma training courses?

Each Belt examination includes multiple-choice and scenario-based questions. The test duration and passing criteria vary by level, ensuring fair assessment of both theoretical understanding and practical application.

Why choose BGMC for Lean Six Sigma Certification Training?

The duration depends on the Belt level:

Yellow Belt: 2–3 Days

Green Belt: 5 Days

Black Belt: 8–10 Days

Master Black Belt: 10–12 Days

Flexible study options are available to suit professional schedules.

Where can I take Lean Six Sigma Certification training in the United Kingdom?

BGMC provides internationally accredited Lean Six Sigma programs led by certified Master Black Belt instructors. Our courses feature real-world case studies, interactive learning, and practical project support — ensuring both academic excellence and professional relevance.

What is the starting fee for Lean Six Sigma Certification training in the UK?

BGMC offers Lean Six Sigma Certification courses across multiple UK locations, as well as virtual and self-paced online options, providing flexibility for both local and international learners.

Why we're the go to training provider for you

Best price in the industry

You won't find better value in the marketplace. If you do find a lower price, we will beat it.

Trusted & Approved

Recognised by leading certification bodies, we deliver training you can trust.

Many delivery methods

Flexible delivery methods are available depending on your learning style.

High quality resources

Resources are included for a comprehensive learning experience.

Success Stories To Inspire

Waseem Shahzad Mehar

Alhamdulillah! I’m delighted to share that I’ve earned my Lean Six Sigma Black Belt Certification from the International Lean Six Sigma Institute (ILSSI).

Hammad Jamshaid

I’m pleased to share that I’ve successfully obtained my PMP® Certification Training – 35 PDUs Certificate from BGMC – Bilal Consultancy Limited!

Engr. Ibrahim Shahid

I’m thrilled to announce that I’ve successfully achieved the NEBOSH International General Certificate in Occupational Health and Safety.

Arslan Aslam

I’m pleased to share that I’ve successfully earned my ISO 9001:2015 Lead Auditor Certification. Grateful to BGMC – Bilal Consultancy Limited for the valuable training and support throughout this journey.

Masooma Bakhtawar

I’m pleased to share that I have successfully completed the ISO 45001:2018 Occupational Health and Safety Management System Lead Auditor Certification.

Sunday Odibo

Proud to be certified as a Lead Auditor for ISO 45001:2018 – Occupational Health and Safety Management System, accredited by Exemplar Global, USA.

ARUNCHUNAI GANESAN

Safety Coordinator At SAMA ENERGY COMPANY, ISO 45001:2018 Occupational Health & Safety Management System & ISO 14001:2015 Environmental Management System (EMS) Lead Auditor certification

Aijaz Mughal

Deputy Manager Quality Operations at Hudson Pharma, ISO 45001:2018 Occupational Health and Safety Management System Lead Auditor Certificate

Muhammad Tahir Rashid

Deputy Manager (IE) Combined Fabrics Limited, NEBOSH IGC

Karam Elahi

Senior Quality control Specialist At Shinebed International, Lean Six Sigma Black Belt

Benjamin Green

Storeroom Technician, Lean Six Sigma Yellow Belt