Pressure Equipment

Directive

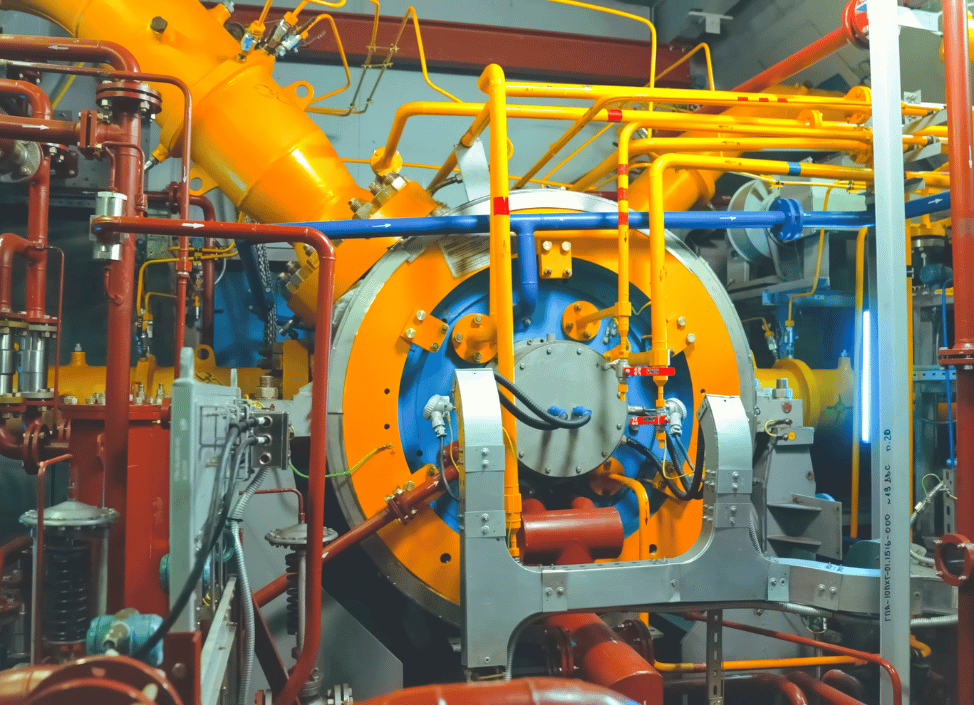

The Pressure Equipment Directive (PED 2014/68/EU) is the European Union’s mandatory regulatory framework governing the design, manufacture, testing, and conformity assessment of pressure equipment and assemblies with a maximum allowable pressure greater than 0.5 bar.

It applies to pressure vessels, piping, boilers, heat exchangers, safety accessories, industrial systems, and a wide range of process equipment used globally.

BGMC supports organizations—manufacturers, exporters, EPCs, and industrial facilities—in achieving full PED conformity, documentation readiness, risk assessment, and inspection compliance, ensuring their products meet EU requirements before being placed on the European market.

Why PED Compliance Matters

Non-compliance can lead to:

Rejection of equipment at EU borders

Legal penalties and liability exposure

Safety hazards and operational failures

Loss of market access and export opportunities

Invalid CE marking or product recall

BGMC ensures your pressure equipment meets the essential safety requirements (ESRs) of the PED, enabling smooth CE marking and acceptance in European markets.

Our Inspection Services

Scope of BGMC PED Services

The scope of BGMC’s PED Services includes verifying compliance of pressure equipment with regulatory requirements, ensuring safe design, manufacturing, testing, and documentation in line with international pressure equipment directives.

PED Classification & Category Determination

We help determine the correct PED category by evaluating the fluid group, equipment type, pressure–volume product, temperature limits, and overall hazard profile. Accurate classification provides the foundation for selecting the appropriate conformity assessment route and achieving CE marking compliance.

echnical Documentation Review & Gap Assessment

BGMC evaluates design files and calculations, material specifications and certificates, welding documentation (WPS, PQR, WPQ), NDT requirements, and compliance with PED Essential Safety Requirements and Annex I risk assessments. Through this review, we identify gaps and recommend the necessary improvements to ensure full alignment with EU regulatory expectations.

CE Marking Support & Conformity Assessment

We guide clients through the full PED conformity process by helping select the correct conformity module, preparing complete technical documentation, and supporting interactions with Notified Bodies. Our team ensures compliance with harmonized standards such as EN 13445, EN 13480, EN 12952, and EN 12953, and verifies final CE Marking readiness. While BGMC is not a Notified Body, we act as your technical partner to ensure documentation and quality systems are fully audit-ready.

PED Inspection & Testing Support

We support all required PED inspections, including design and material verification, welding qualification checks, NDT and quality evaluations, hydrostatic or pneumatic pressure testing, final visual inspection, and verification of safety accessories. Our engineers ensure each inspection aligns with the selected conformity module and meets Notified Body expectations.

Quality Management System (QMS) Assistance for PED Modules

For manufacturers operating under Modules D, D1, E, or H, we provide support in developing a PED-aligned Quality Management System, conducting internal audits, preparing process documentation, and establishing production control and traceability requirements. We also integrate these elements with ISO 9001 or existing IMS frameworks to ensure long-term compliance and smooth surveillance audits.

PED Training & Awareness for Engineers & QA Teams

BGMC delivers specialized training covering PED fundamentals, category and module selection, interpretation of Essential Safety Requirements, CE marking obligations, technical documentation preparation, and welding/NDT requirements under PED. We also train teams on effectively working with Notified Bodies, enabling them to confidently manage future PED-related projects.

Why Choose BGMC for PED Support?

We support PED compliance for:

Every project includes:

Sample Use Cases

How It Works

Case 1 – Pressure Vessel Manufacturer (Export to EU)

BGMC performed PED classification, reviewed design calculations, supported welding qualification, and prepared the technical documentation for a Notified Body review.

Case 2 – Heat Exchanger OEM

We aligned their QMS with Module H requirements, trained the QA team, updated procedures, and ensured CE marking compliance.

Case 3 – Skid Assembly for Chemical Plant

BGMC established conformity pathways for assemblies involving vessels, piping, and safety accessories, integrating the PED ESRs across the entire skid.

successful projects & satisfied customers.

Inspired by our work?

Need expert support for PED compliance, documentation, or inspection for EU export?

BGMC ensures your pressure equipment meets all regulatory, safety, and technical expectations.