Energy & Natural Resources

Why Automotive & Mobility Must Transform Now

We begin with a comprehensive 360° assessment of your energy and natural-resources operations — from upstream extraction to downstream processing and distribution.

Our diagnostic identifies systemic gaps in stability, equipment reliability, operational discipline, and safety performance.

We evaluate:

• Variability in daily production performance

• Delays, stoppages, and operating inefficiencies

• Micro-interruptions that reduce output and increase cost

• Safety exposures, near-miss patterns, and procedural gaps

• Waste points, energy losses, and avoidable resource consumption

• Causes of quality deviations in fuels, minerals, or processed materials

• Skill gaps that impact safe and efficient operations

• Supply disruptions affecting material flow and site productivity

This stage creates a factual foundation for a long-term improvement roadmap that reflects actual field behavior, not assumptions.

BGMC’s Transformation Approach for Energy & Natural Resources

Assess Operational Systems & Risk Exposure

We evaluate the current performance of production systems, assets, safety controls, and environmental processes to identify critical risks and improvement opportunities. Our assessments ensure organizations gain clarity on reliability gaps, energy inefficiencies, and environmental vulnerabilities.

Assessments include:

• Asset reliability audits & failure-pattern analysis

• Environmental compliance checks (ISO 14001, ESG indicators)

• Energy efficiency & resource-utilization assessments

• Safety culture and operational-risk evaluations

Redesign for Safe, Efficient & Sustainable Operations

We redesign operational workflows to improve stability, eliminate bottlenecks, reduce safety risks, and minimize energy waste. Our redesigned systems help improve throughput, strengthen environmental performance, and ensure consistent compliance across facilities.

Activities include:

• Lean workflow optimization

• Hazard & risk reduction planning

• Energy and emissions reduction programs

• Standardization of safe operating procedures

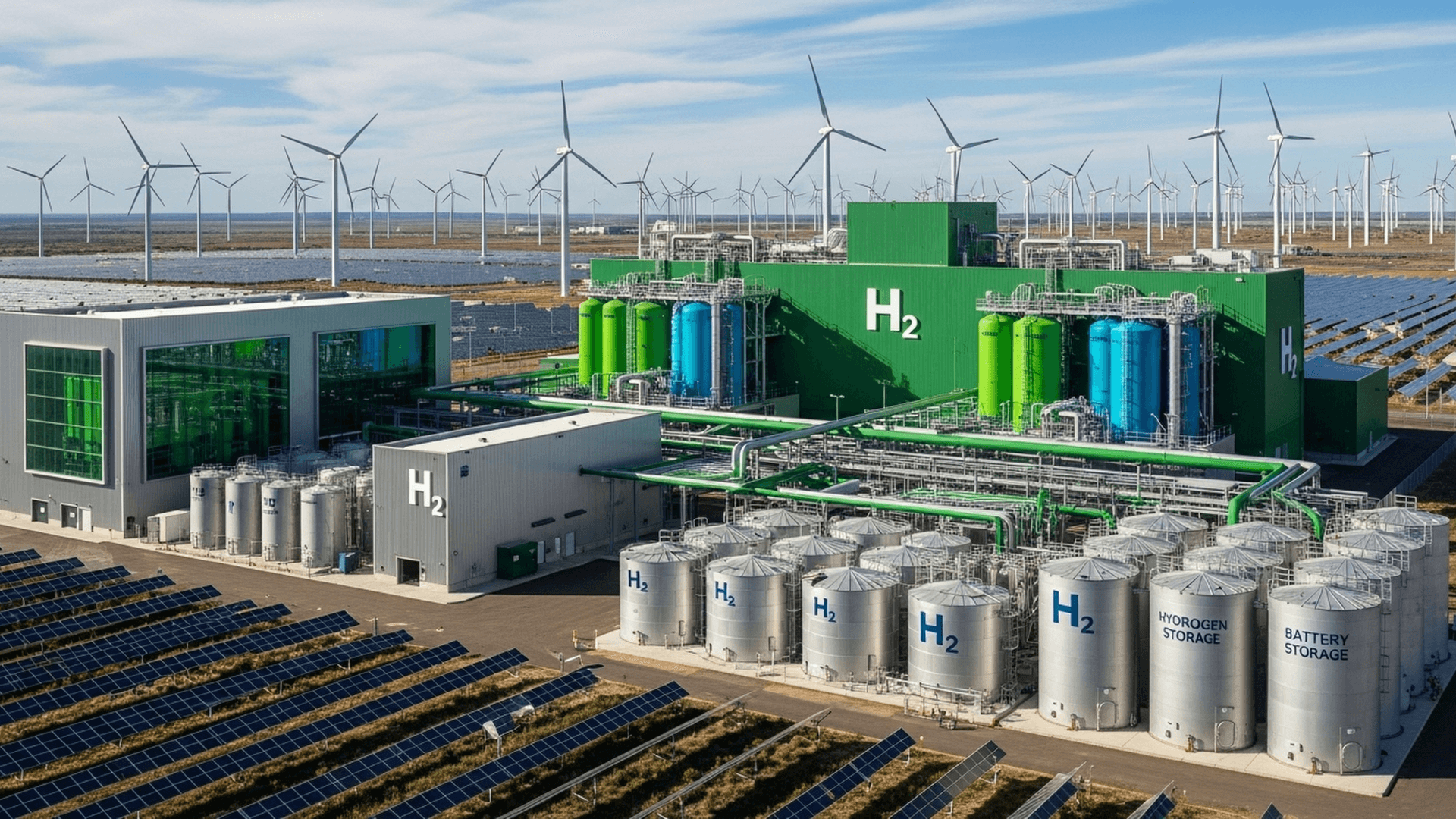

Deploy Predictive Tools, Digital Systems & Automation

We help organizations shift from reactive to predictive, data-driven operations using IoT sensors, digital dashboards, and automated monitoring tools. Digitalization enhances transparency, reliability, and environmental accuracy.

Solutions include:

• Predictive maintenance using IoT, AI & condition monitoring

• Digital twins for asset and process simulation

• SCADA, DCS & automated compliance reporting

• Real-time energy & emissions monitoring systems

Standardize & Scale Improvements Across Sites

We build standardized systems that enable organizations to scale operational excellence across mines, plants, rigs, and utility sites. This creates unified ways of working, consistent safety standards, and sustainable long-term performance.

Capabilities include:

• Enterprise-wide SOPs & maintenance frameworks

• ISO & ESG integration for multi-site operations

• Unified dashboards for KPIs and compliance

• Cross-site audits and governance systems

Build Capability for Long-Term Performance

We develop the workforce capabilities needed to maintain reliable, safe, and environmentally aligned operations. Our programs support frontline teams, engineers, supervisors, and leaders in adopting new technologies and processes.

Programs include:

• QHSE training & competency development

• Reliability engineering & digital tools training

• Sustainability & ESG capability building

• Leadership coaching for operational excellence

Our Consumer Products Excellence Operational Offerings

Operational Excellence & Production Optimization for Energy & Natural Resources

We help upstream, midstream, downstream, mining, refining, utilities, and renewable-energy operations improve production stability, reduce variability, and enhance workforce performance. Our approach strengthens process discipline and optimizes flow across extraction, processing, distribution, and asset-heavy environments.

Services include:

Lean process redesign for field, plant & utility operations

Cycle-time optimization for drilling, extraction & processing

Production workflow stabilization & bottleneck removal

Loss analysis for downtime, flaring, leaks & yield gaps

Standard operating procedures for safe, consistent operations

Visual management & daily control-room routines

Material movement and logistics flow improvement

Example outcomes:

Higher production reliability, improved throughput, and reduced operational losses.

Procurement Optimization for Fuels, Raw Materials, Parts & Engineering Services

We optimize sourcing and inventory for bulk materials, engineering spares, chemicals, fuels, safety equipment, and contractor-managed services across the energy sector.

Services include:

Supplier qualification & contract governance

Bulk material procurement optimization

Inventory planning for critical spare parts & long-lead items

Warehouse & yard layout optimization for industrial storage

Vendor risk assessment & performance monitoring

Strategic sourcing for maintenance & shutdown services

Example outcomes:

Reduced procurement cost, improved material availability, fewer shutdown delays.

Integrated ISO Systems for High-Risk Energy & Natural Resources Environments

Energy-sector organizations must meet strict quality, safety, and environmental obligations.

Services include:

ISO 9001 (Quality), ISO 14001 (Environment), ISO 45001 (Safety)

ISO 50001 (Energy Management System)

Documentation, SOPs & EHS risk registers

Internal audits & compliance programs

Emergency preparedness & chemical/environmental controls

Example outcomes:

Stronger compliance, reduced risk exposure, improved audit readiness.

Quality Excellence for Stable, Safe & Reliable Energy Operations

We enhance quality systems for exploration, mining, generation, refining, pipelines, and distribution operations.

Services include:

Process capability & stability improvement

Defect analysis for refining, drilling & extraction deviations

Quality checkpoints across processing & handling

Calibration, instrumentation & measurement accuracy systems

Reliability engineering & equipment performance analysis

Control plans for operational-critical processes

Example outcomes:

Fewer deviations, higher reliability, improved stakeholder confidence.

HSE Excellence & Risk Control for Hazardous Energy Environments

Risk levels in energy and natural resources are among the highest of any industry. We strengthen HSE systems to protect people, assets, and the environment.

Services include:

HSE audits for plants, rigs, mines & utility operations

HAZOP, risk assessment & process safety management

Fire, explosion & toxic-gas hazard identification

LOTO for high-energy equipment & confined space controls

Environmental management for emissions, effluents & waste

Emergency response, drills & crisis management

Example outcomes:

Fewer incidents, stronger safety culture, improved regulatory compliance.

Energy Project Management, Capital Programs & Turnarounds

We manage major energy projects—new wells, plant upgrades, shutdowns/turnarounds (TAR), expansions, renewable installations, and digital transformation initiatives—with strong governance and execution discipline.

Services include:

PMO setup for engineering & capital projects

Detailed project scheduling & risk mitigation

EPC contractor oversight & performance tracking

Turnaround planning, execution & post-TAR stabilization

Safety & environmental risk management for projects

Commissioning readiness & performance validation

Cost control, resource planning & reporting

Example outcomes:

On-time project delivery, reduced overruns, and safer, more efficient execution.

Energy Supply Chain, Procurement & Logistics Optimization

We help energy companies manage complex supply chains involving long-lead equipment, hazardous materials, drilling supplies, chemicals, tools, and high-value spares.

Services include:

Supplier qualification, evaluation & risk management

Logistics optimization for rigs, terminals & remote sites

Inventory optimization for critical parts & chemicals

Warehouse layout design, safety & compliance improvements

Strategic sourcing for cost reduction & service-level improvement

Demand planning for drilling, maintenance & production cycles

Import/export & customs compliance support

Example outcomes:

Lower supply disruptions, improved availability of critical items, and reduced logistics costs.

Digital & Automation Solutions for Energy Reliability, Safety & Efficiency

We apply advanced digital technologies to modernize operations, reduce downtime, and enable predictive decision-making.

Services include:

Digital twins for plants, rigs, mines & grids

IoT monitoring for temperature, vibration, pressure & flow

Predictive maintenance for turbines, compressors, conveyors & pumps

AI models for production forecasts, load balancing & failure prediction

Real-time dashboards for safety, operations & energy consumption

ERP/SCADA integration for end-to-end operational visibility

Example outcomes:

Higher asset reliability, fewer failures, smarter and safer energy operations.

TECHNOLOGY STACK FOR CONSUMER PRODUCTS EXCELLENCE

Example Use Cases & Outcomes

Personal Care Manufacturer High-Speed Filling Line Optimization

A large personal care brand faced fluctuations in line speed, inconsistent fill accuracy, and frequent micro-stoppages that created backlogs in packaging.

Challenge:

Unstable throughput caused by inconsistent dosing, minor stoppages, and delayed changeovers between variants.

Solution:

Cycle-time stabilization, filling-nozzle optimization, SMED implementation, predictive maintenance deployment, and real-time line-performance dashboards.

Outcome:

Throughput increased by 22%, fill-level variation decreased significantly, and overall line reliability improved across all shifts.

Snacks & Confectionery Plant — Packaging Accuracy & Quality Consistency

Multiple SKUs and pack sizes caused errors in labeling, sealing, and weight accuracy, leading to customer complaints and rework.

Challenge:

High defect rates in packaging due to manual checks and lack of real-time detection.

Solution:

Vision systems for defect detection, integrated labeling-verification tools, SPC implementation, and root-cause elimination of packaging issues.

Outcome:

40% reduction in consumer complaints, improved audit readiness, and higher first-pass quality across all production lines.

Household Cleaning Products Downtime Reduction & Reliability Upgrade

A cleaning-products facility experienced frequent equipment stoppages and unpredictable machine failures across mixing and bottling lines.

Challenge:

Unplanned downtime, maintenance overload, and inconsistent equipment performance.

Solution:

Asset-criticality ranking, predictive maintenance deployment, lubrication and inspection standards, and reliability-centered maintenance routines.

Outcome:

Breakdowns reduced by 30%, OEE increased across bottling lines, and maintenance costs stabilized.

E-Commerce-Focused Brand Inventory Stability & ERP Integration

Demand fluctuations caused stockouts of top-selling SKUs and overstocking of slow movers, impacting fulfillment reliability.

Challenge:

Poor forecasting accuracy and weak visibility across production, warehouse, and order flow.

Solution:

AI-based demand forecasting, ERP-driven planning improvements, optimized inventory parameters, and redesigned warehouse material flow.

Outcome:

Forecast accuracy improved by 35%, inventory waste reduced, and service levels increased across online channels.

Who We Serve

Industries

- Food & Beverage

- Personal Care

- Cosmetics

- Household Cleaning Products

- OTC Consumer Health Products

- Snacks & Confectionery

- Packaging & Bottling

- E-Commerce Consumer Brands

- Logistics & Warehousing

Functions

- Operations

- Production

- Maintenance

- Quality

- Supply Chain

- Planning

- R&D / Product Development

- HSE / QHSE

- Leadership & Plant Management

Regions

Frequently Asked Questions

1. How do we begin improving performance in a consumer-products plant?

2. Can BGMC help reduce quality issues and customer complaints?

3. Do you support regulatory and ISO compliance?

4. Can BGMC support digital transformation for consumer-product factories?

5. How do you help stabilize multi-SKU, fast-changeover environments?

6. Do you help improve warehouse and distribution performance?

Ready to Transform Your Manufacturing Operations?

Let’s discuss how BGMC Group can help transform your operations and drive measurable results.

Connect with our experts today to explore customized industrial and business solutions designed for your success.

We work with ambitious leaders who want to define the future, not hide from it. Together, we achieve extraordinary outcomes.