Lifting equipment & accessories

Lifting operations involve some of the highest-risk activities in industrial, construction, and logistics environments. Failures of cranes, hoists, slings, shackles, hooks, and rigging gear can cause severe accidents, production stoppages, costly damage, and regulatory penalties.

BGMC provides independent, third-party inspection and certification of lifting equipment and lifting accessories to help organizations maintain safe lifting practices, achieve compliance, and prevent incidents. Our inspections are conducted in accordance with ISO/IEC 17020 principles, international lifting standards, and client-specific requirements.

Why Lifting Equipment Inspection Is Essential

Lifting equipment deteriorates due to:

Overloading

Wear and tear

Corrosion

Misuse or improper rigging

Mechanical failure

Fatigue and deformation

Without periodic inspection:

❌ Equipment failures may cause serious injuries

❌ Loads may drop unexpectedly

❌ Structural failures or wire rope snapping may occur

❌ Legal and insurance compliance may be compromised

❌ Project delays and financial losses increase

Our Inspection Services

Scope of BGMC Lifting Equipment & Accessories Inspection

The scope of BGMC’s Lifting Equipment & Accessories Inspection includes assessing the condition, safety, and compliance of lifting machines and accessories to ensure safe operation, prevent failures, and meet regulatory and industry standards.

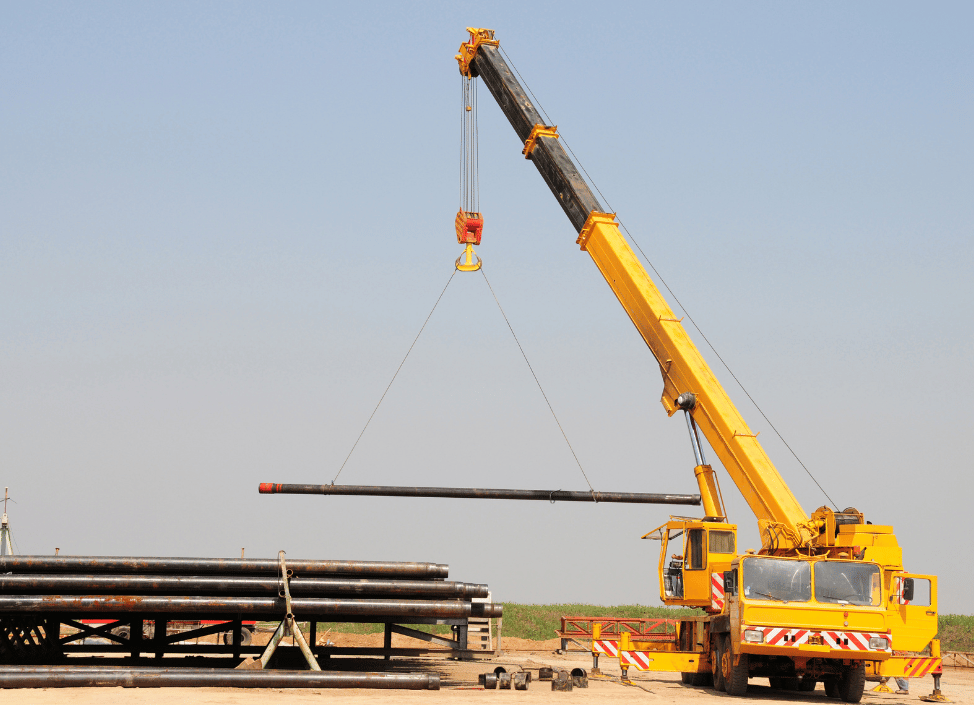

Mobile Cranes

We assess lifting equipment through structural integrity checks, inspection of booms, jibs, and hook blocks, verification of outriggers and leveling systems, evaluation of load indicators and limit switches, wire rope condition assessments, and hydraulic system checks to ensure safe and compliant operation.

Overhead Cranes & Gantry Cranes

We inspect overhead cranes by verifying trolley and bridge alignment, checking rail conditions and end stops, assessing hoist mechanisms, examining electrical panels and brakes, and testing limit switches and other safety devices to ensure reliable and safe operation.

Forklifts & Telehandlers

We evaluate forklifts by inspecting the mast, carriage, and forks; assessing hydraulic systems; checking tyres, brakes, and steering; verifying safety alarms and seatbelts; and ensuring all operator controls function properly for safe and efficient use.

Hoists & Winches

We assess hoists by checking chain and rope health, evaluating gearbox condition, verifying brake performance, measuring load chain stretch, and identifying any deformation in lifting hooks to ensure safe and reliable operation.

MEWPs

We inspect MEWPs by evaluating platform and guardrail integrity, testing emergency lowering systems, assessing hydraulic components, and performing stability checks to ensure safe operation at height.

Inspection of Lifting Accessories

Inspection of lifting accessories includes evaluating slings, shackles, hooks, eye bolts, chain blocks, wire ropes, and other rigging components for wear, deformation, corrosion, cracks, and load-rating compliance. This ensures accessories remain safe, reliable, and fit for lifting operations.

Industry Sectors Using BGMC Lifting & Rigging Inspection Services

Corroded or thinned chains

Hook deformation or twist

Cracked welded joints

Ineffective brakes

Faulty limit switches

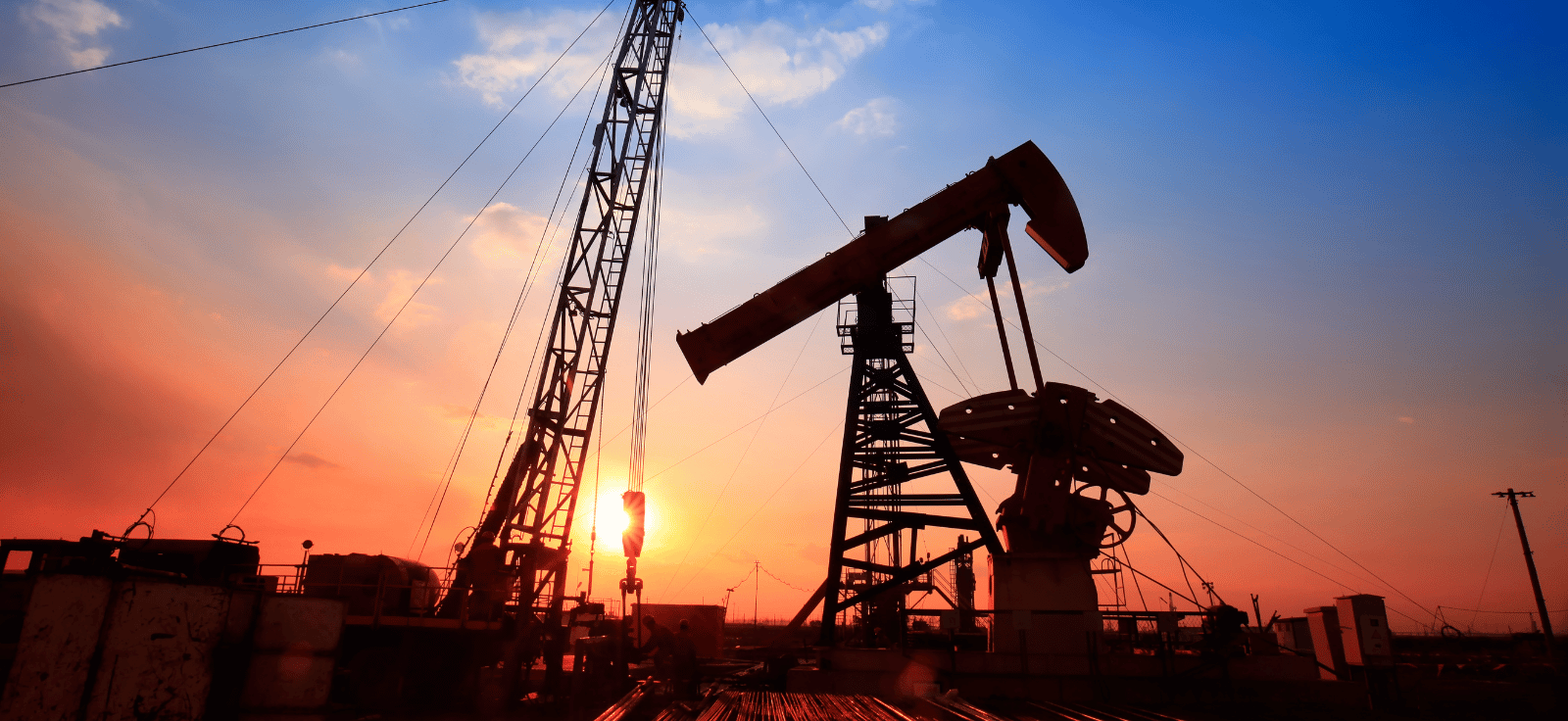

Oil & Gas

Manufacturing

Logistics & Warehousing

Marine & Ports

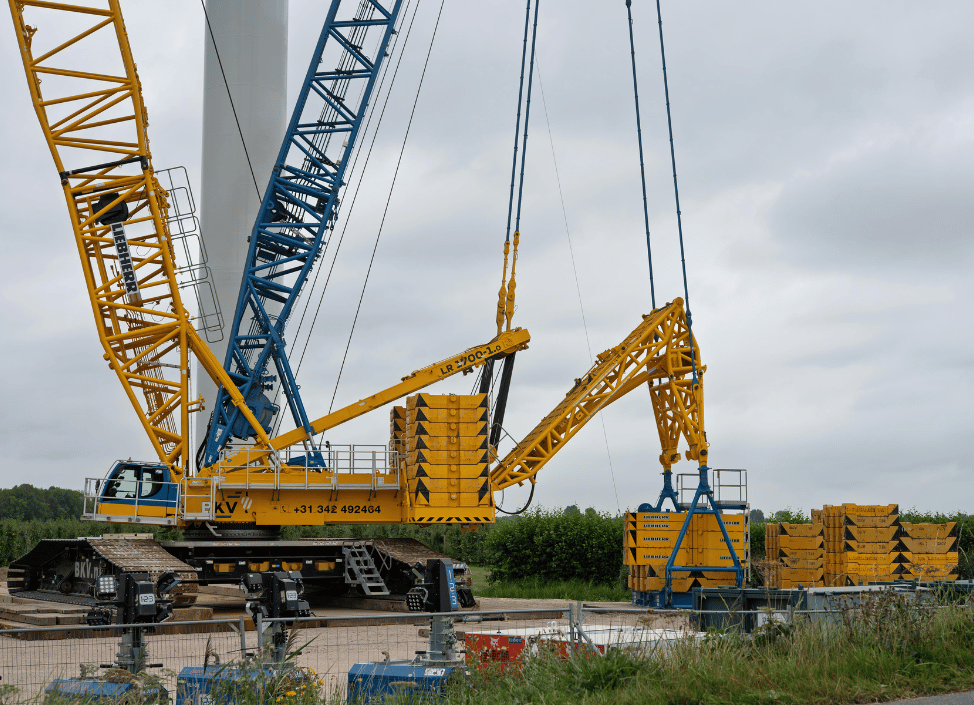

Utilities & Power

Sample Use Cases

How It Works

Scenario 1 – Construction Crane Safety Program

BGMC conducted functional safety checks and load testing for tower cranes, improving site safety and passing regulatory checks.

Scenario 2 – Warehouse Equipment Compliance

Forklift inspections and operator training reduced incident rates and improved maintenance cycles.

Scenario 3 – Industrial Machine Safety Audit

A manufacturing plant required third-party verification to meet client audit criteria; BGMC ensured compliance and operational readiness.

successful projects & satisfied customers.

Inspired by our work?

Need reliable inspection and certification for your lifting equipment and accessories?

BGMC ensures your lifting operations are safe, compliant, and ready for use.