Steam Boiler Inspection Services

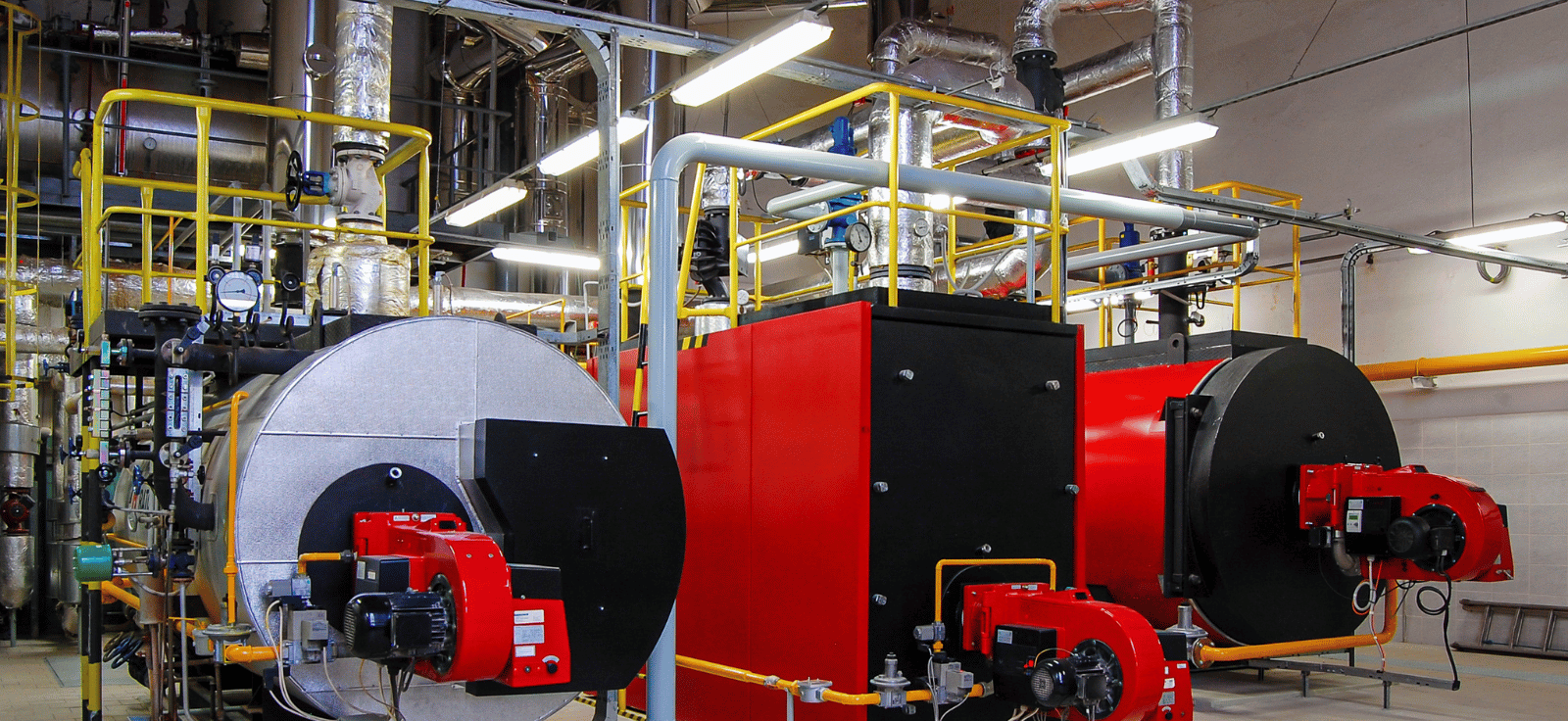

Steam boilers are critical components in manufacturing, energy production, food processing, chemical plants, pharmaceuticals, textiles, and HVAC systems. Improper maintenance or delayed inspections can lead to catastrophic failures, severe injuries, costly shutdowns, and legal non-compliance.

BGMC provides independent, third-party Steam Boiler Inspection Services designed to ensure the safe operation, regulatory compliance, and long-term reliability of steam generation systems. Our inspections follow internationally recognized best practices and support compliance with regulatory requirements, OEM guidelines, and industry codes.

We operate using the principles of ISO/IEC 17020, ensuring impartial, objective, and technically competent inspection processes.

Why Steam Boiler Inspection Is Essential

Steam boilers face continuous exposure to high pressure, temperature, corrosion, and mechanical stresses. Without periodic inspection:

Boiler explosions may occur

Energy efficiency drops significantly

Scaling and corrosion reduce boiler lifespan

Safety valves may malfunction

Heat exchanger tubes can fail

Operators may face legal penalties

Insurance coverage may be affected

Regular boiler inspection ensures performance, safety, compliance, and cost control.

Our Inspection Services

Scope of BGMC Steam Boiler Inspection Services

The scope of BGMC’s Steam Boiler Inspection Services includes assessing boiler condition, safety devices, pressure components, operational performance, and regulatory compliance to ensure safe, efficient, and reliable boiler operation.

External Inspection

A thorough external inspection covers the boiler shell and external surfaces, insulation condition, mountings and valves, water level indicators, and associated piping systems and joints. It also includes verifying the foundation, alignment, safety interlocks, and instrumentation. This assessment identifies visible defects and ensures the equipment is safe and ready for internal inspection.

Internal Inspection

Our inspectors examine internal boiler components for scale, corrosion, and pitting, assess tube conditions for erosion, cracking, or thinning, and review the furnace, firebox, refractory, steam drum, and mud drum. They also verify weld integrity, manhole and handhole fittings, and overall internal cleanliness. This internal inspection confirms the mechanical integrity of all critical pressure boundaries.

Operational Inspection

We evaluate the boiler under operating conditions by assessing combustion quality, steam pressure stability, water level control, feedwater pump performance, safety valve lift tests, burner and flame behavior, and emission levels where applicable. This operational assessment ensures optimal performance and confirms that the boiler responds correctly and safely during real working conditions.

Safety Device Inspection & Testing

We verify the accuracy and functionality of safety relief valves, low water cut-off devices, pressure gauges and sensors, temperature indicators, automatic shut-off systems, flame failure protections, and all related alarms and interlocks. These critical components ensure safe operation and play a vital role in preventing boiler accidents.

Non-Destructive Testing

BGMC supports complete NDT examination through our specialized partners, including Ultrasonic Thickness Testing, MPI/DPI for weld evaluation, radiography when required, hardness testing, and eddy current testing for tubes. These NDT methods verify the hidden integrity of boiler materials and welds, ensuring safe and reliable operation.

Boiler Efficiency & Performance Assessment

We analyze fuel consumption versus steam output, heat losses, efficiency trends, combustion air settings, blowdown practices, and water chemistry control. These assessments help reduce energy costs, enhance efficiency, and improve overall boiler operational reliability.

BGMC’s Approach to Steam Boiler Inspection

Manufacturing

Textiles

Food & Beverage

Chemicals

Pharmaceuticals

Oil & Gas

Corrosion & pitting

Scale deposits

Tube leaks

Cracked refractory

Faulty safety valves

Erosion at bends or welds

Sample Use Cases

How It Works

Case 1: Boiler Safety Compliance Assessment

A manufacturing plant needed a full inspection to meet regulatory requirements. BGMC performed external and internal boiler examinations, checked safety devices, reviewed NDT results, and verified operational controls. The plant achieved compliance and cleared its annual safety audit without observations.

Case 2: Performance & Efficiency Optimization

A textile facility reported high fuel consumption and unstable steam output. BGMC conducted a boiler performance assessment, analyzing combustion efficiency, heat losses, and water chemistry. Corrective actions improved efficiency by 12% and stabilized steam pressure during peak production.

Case 3: Shutdown Boiler Integrity Verification

An industrial site required boiler readiness checks before restarting after a shutdown. BGMC performed tube inspections, refractory evaluation, pressure part integrity checks, and safety valve verification. The boiler was declared fit for service, enabling safe and timely plant restart.

successful projects & satisfied customers.

Inspired by our work?

Need to ensure the safety, compliance, and efficiency of your steam boiler?

BGMC provides reliable and comprehensive boiler inspection services that protect your plant and personnel.