Design of Experiments (DOE) is a powerful statistical tool that has revolutionized the way experiments are conducted and analyzed across various fields. Whether you are a scientist, engineer, or business professional, understanding DOE can greatly enhance your ability to optimize processes, improve product quality, and make data-driven decisions. However, many individuals shy away from DOE due to its perceived complexity and technical nature. In this comprehensive guide, we aim to demystify DOE and provide you with a clear understanding of its principles, methodologies, and real-life applications. Through practical examples and step-by-step explanations, you will learn how to effectively design experiments, analyze data, and draw meaningful conclusions. Get ready to unlock the full potential of DOE and unleash its transformative power in your own work.

Design of Experiments (DOE)

Design of Experiments (DOE) is a powerful data collection and analysis tool that can be used in various experimental scenarios. It allows researchers and analysts to explore and understand complex systems efficiently. It is widely used in various fields, including manufacturing, engineering, healthcare, and marketing, to name a few. DOE involves systematically varying input variables to observe and analyze their impact on the output or response variable of interest. By carefully designing and conducting experiments, DOE helps to uncover the cause-and-effect relationships between variables, leading to more informed decision-making and problem-solving.

Benefits of DOE

- Efficiency: Reduces time and resources

- Cost Savings: Lowers research and production costs

- Optimization: Identifies ideal conditions

- Enhanced Quality: Improves product quality

- Data-Driven: Informs decisions with data

- Faster Problem-Solving: Speeds issue resolution

- Comprehensive Insights: Reveals complex interactions

- Statistically Valid: Ensures reliable results

- Collaboration: Encourages cross-functional teamwork

- Risk Mitigation: Identifies and mitigates risks

- Continuous Improvement: Promotes ongoing enhancement

- Versatility: Applicable in diverse fields

When to use DOE

- Employ DOE when you have reasons to believe that more than one input factor could influence a particular output or outcome.

- It is useful when you need to understand how these input factors interact and affect the output in a complex manner.

- DOE can help confirm suspected relationships between inputs and outputs, validating your hypothesis.

- It allows you to create predictive equations or models, which can be used for what-if analysis and making informed decisions.

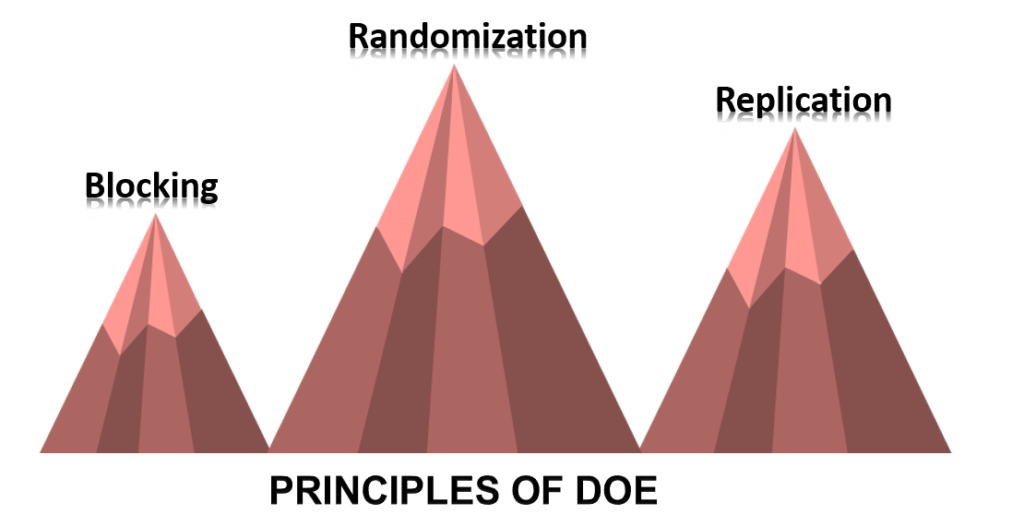

Principles of DOE

Design of Experiments (DOE) is a powerful approach that plays a pivotal role in the success of research studies and experiments across diverse fields. This methodology empowers researchers to optimize their experiments, enhance reliability, and reduce costs, yielding more accurate and dependable results. By adhering to fundamental DOE principles and methodologies, researchers can ensure the validity and robustness of their experiments, paving the way for informed decision-making.

Randomization

The first principle of DOE is randomization, which describes the sequence in which experiment trials are conducted. It encourage fairness and impartiality in experimentation. Randomization involves

- Assigning factors and conditions randomly to experimental units.

- Ensuring that each condition has an equal opportunity for testing.

This critical step is important in obtaining unbiased and statistically valid results, as it removes the influence of uncontrolled variables and confounding factors, laying the foundation for credible conclusions.

Replication

Replication stands as the second vital principle in DOE. It involves experimenting multiple times under identical conditions. This repetition accounts for variability and assesses the consistency and reliability of results. By replicating experiments, researchers can identify the degree of variation within their data, bolstering confidence in the outcomes and providing a measure of the experiment’s reproducibility.

Blocking

Blocking is another critical DOE principle. It involves grouping experimental units into homogeneous blocks based on factors that may influence the response variable. This process helps eliminate potential confounding effects, enhancing the experiment’s precision. By blocking, researchers can separate and control the influence of these factors, leading to more accurate and insightful results.

Insights gained from a well-executed Experiment

- Identification of Critical Process Factors.

- Determination of Optimal Performance Settings.

- Analysis of Main and Interaction Effects.

- Minimized Output Variability.

Methodology of DOE

The methodology of DOE encompasses several vital steps. It begins with identifying factors that could impact the response variable and selecting appropriate levels for these factors. Subsequently, researchers design the experimental plan, determining the number of experimental units, the order in which conditions are tested, and the allocation of treatments. These careful planning steps ensure that the experiment is conducted efficiently and effectively.

Steps to Design and Analyze Experiments

Step 1: Define the Objective

The initial step in the DOE process is to clearly define your objective. What specific outcome or result are you aiming to achieve or understand through your experiment? Once you’ve established a clear objective, identify the factors that have the potential to influence this outcome. These factors may include variables.

Step 2: Determine the Experimental Design

In the second step, you must select an appropriate experimental design. There are several DOE techniques available, each suited to different scenarios. Options include full factorial design, fractional factorial design, and response surface methodology. The choice of design depends on factors such as the number of variables, the levels they have, and the resources at your disposal.

Step 3: Assign Levels to Factors and Plan the Experiment

Following your chosen experimental design, assign specific levels to each factor. These levels represent the various settings or conditions at which you’ll test the factors. It’s crucial to select levels that are meaningful and directly relevant to your experiment’s objective. Once levels are assigned, plan the experiment by determining the number of runs or trials required to comprehensively explore the factor interactions.

Step 4: Conduct the Experiment and Collect Data

With your experiment planned, proceed to carry out the actual trials. Ensure that you adhere to the experimental design, and carefully record data for each run. To obtain accurate and reliable results, it’s vital to maintain controlled conditions during the experiment to minimize potential sources of variability.

Step 5: Analyze the Data and Draw Conclusions

Once you’ve collected the data, the fifth step is to analyze it using statistical methods. This analysis will enable you to uncover relationships between the factors and the response variable. Tools like analysis of variance (ANOVA), regression analysis, and graphical techniques can be employed to interpret the results. Based on the analysis, draw conclusions and make informed decisions regarding which factors significantly impact the desired outcome.

Step 6: Optimize and Validate the Results

If your primary goal is process or system optimization, you can utilize the insights gained from the data analysis to identify the optimal levels for the factors. This optimization helps you efficiently achieve the desired outcome. Additionally, it’s crucial to validate the results by conducting further experiments or tests to ensure the findings are robust and dependable.

By methodically following these six steps in the Design of Experiments (DOE) process, you can effectively design and analyze experiments in various fields.

Applications of DOE

Design of Experiments (DOE) is not just for theory and labs, it Is used in many industries in the real world. Its versatile nature empowers decision-makers and problem solvers to harness its potential for tangible benefits. One prominent application of DOE is in product development, where it aids companies in refining their offerings. By systematically conducting experiments, companies can pinpoint the critical factors affecting product performance.

Optimizing Manufacturing Processes

DOE plays a pivotal role in process improvement and optimization. Manufacturing processes often involve multiple variables that can influence product quality and efficiency. By applying DOE techniques, companies can methodically analyze these variables and determine the optimal settings. This approach results in substantial cost savings, reduced waste, and heightened productivity.

Conclusion

In conclusion, the Design of Experiments (DOE) is a versatile and powerful tool that has the potential to transform the way experiments are conducted and analyzed across a wide range of fields. Its principles of randomization, replication, and blocking ensure the validity and reliability of results. At the same time, its methodology and statistical analysis techniques enable researchers and professionals to optimize processes, reduce costs, and enhance product quality. DOE’s real-life applications in product development, manufacturing, marketing, and other industries underscore its practical significance. Embracing DOE opens the door to comprehensive insights, data-driven decisions, and continuous improvement, making it an indispensable asset for anyone seeking to excel in their work. So, please do not shy away from DOE’s perceived complexity; instead, embrace it as a valuable tool that can unlock the full potential of your experiments and projects.